Inspection Methods and Rules for Steel Silo - Part 3

Inspection Methods of Steel Silo

Welding Quality Inspection

Welding quality shall take three-grade inspection method according to GB50205.

Installation Quality Inspection

- Auxiliary hole installation inspection: Observation inspection.

- Horizontal cutting inspection of upper and bottom planes of silo: Observation inspection.

- The undercut shape inspection of silo: Observation inspection.

For liquid container, silo shall have a loading test: Observation in 48 hours.

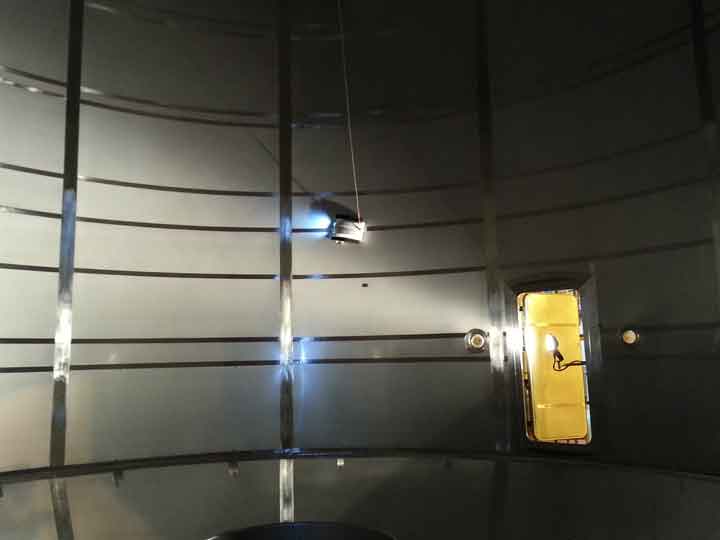

Appearance Quality Inspection

- Guardrail inspection: Observation inspection

- Surface inspection of silo: Observation inspection

Geometric Tolerance Inspection of Silo

Diameter tolerance inspection of silo: In process of building, first choose one point respectively from upper, middle and lower section of silo in the height direction. Upper point is 2m away from the top, lower point is 1.5m away from the bottom, middle point is at 1/2 distance between upper point and lower point. And then take circumference measurements based on 3 points for 3 results using steel tape, the final circumference result is obtained on average.

Ovality tolerance inspection of silo: Ovality tolerance shall be the difference between maximum and minimum diameters of the measured plane 1.2 meters away from basic plane at lower part of silo.

Vertical tolerance inspection of silo: With help of theodolites and steel tape, deviation from two directions which are perpendicular to each other shall be measured.

Vertical tolerance inspection of silo: choose 3 points to measure it using steel tape.

Vertical tolerance inspection of stiffener: Plumb line and measure it using steel ruler.

Inspection Rules of Steel Silo

Each project shall be inspected by the company quality inspection personnel before delivery and acceptance.

Steel silo acceptance shall be the following inspection and record:

- Welding quality inspection

- Installation quality inspection

- Appearance quality inspection

- Geometric tolerance inspection of silo

Español

Español