Unique Advantages of Details in Steel Silo

To ensure the humane usages of steel silo, Flyer has made great progress in the details of its storage silo. The following are some of these detailed advantages:

The cover plate on the roof is fabricated with hot rolling galvanized sheet instead of common sheet. It is good-looking in appearance and with excellent performance. The working life of the roof can be as long as the silo body;

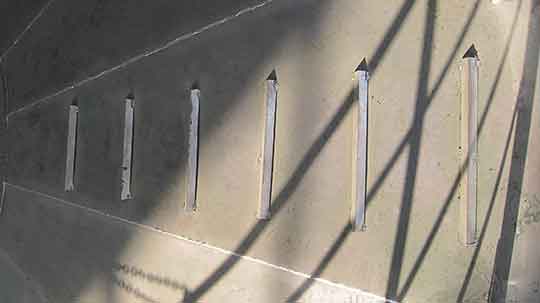

| For the convenience of customs’ doing maintenance work on the roof, non-slip strips are installed on the roof; |

|

| To avoid falling objects, skirting board of -2.0×100 is installed at the bottom of the banister on the roof. |

|

| To prevent dust blocking, the amount of air vent has been added to reduce pressure more evenly. |

|

| The painted components inside the roof help avoid the condensing, a phenomenon that common sheet may have, to extend its serving life and ensure its safety. |

|

| Manufactured with hot-rolling galvanized coil instead of common sheet, the wallboard of silo gate is single-pressed with professional equipments. It has better performance in sealing, anticorrosion, and appearance as well. |

|

| A temporary rest platform and a straight ladder are installed under the silo gate, providing convenience for maintenance. |

|

| For the special steel silo clamping apparatus, Flyer changes iron casting to steel casting, whose material is the same with the welded parts and free from outside temperature impact, avoiding splitting during welding process. |

|

| High strength steel channels are used as internal stiffeners whose sizes are enlarged from top to bottom according to the pressure distribution of the silo body. Two stiffening plates are installed at the joint of two stiffeners for reinforcement. The weld joint is 50mm which conforms to the national standard. The distance between two stiffeners is no more than 1m and the amount of stiffeners are installed according to the size of the silo. |

|

Previous:our advantages

Next:nothing

Get In Touch With

Español

Español