The Application of Coal Silo in Port

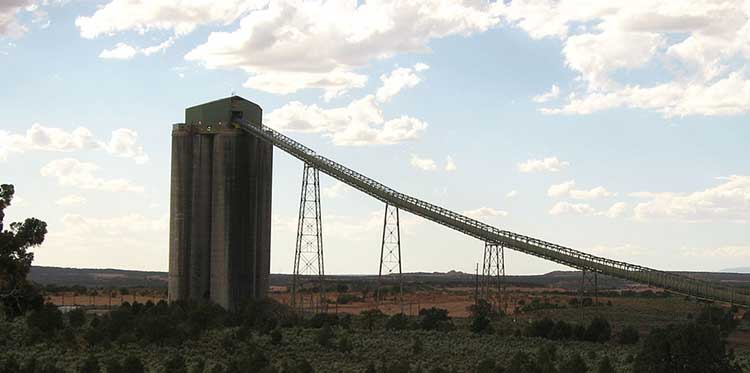

In the traditional port, coal is piled up in the open air, so there are dust and secondary dust produced in the coal handling process. Storage coal by adopting coal silos can solve these dust problems and reduce the cost of coal dust control.At present, coal silos have been widely used in power plants, coal mine enterprises, and other fields. The commonly used coal storage silos include concrete silo and steel silo. The construction period of the concrete silo is long and the investment is high. While the steel silo has the characteristics of a small footprint, high strength, nice appearance, and short construction period, which is favored by grain processing enterprises and bulk grain wharves. At the same time, its application in the building materials industry, chemical industry, sewage treatment industry, and other fields also maintains a strong development momentum.

| Data | Concrete Silo | Steel Silo |

| Construction Period | Long | Short, 1/3-1/2 of the concrete silo |

| Total Weight | Heavy | Light, 1/4-1/5 of the concrete silo |

| Total Investment | High | 20% - 50% less than concrete silo |

| Air Tightness | Slightly bad | Excellent |

| Shock Resistance | Excellent | Slightly bad |

| Detachable | No | Yes |

| Service Life | 60-80 years | 20-50 years |

| Maintenance Cost | Low | Slightly high |

| Installation | On-site construction | Factory prefabrication and on-site assembly |

The outdoor coal storage with steel silos features high efficiency, simple operation, and flexible system scheduling. Besides, we can build a steel silo group to meet the needs of various kinds of coal storage. They all have the functions of coal storage and coal blending, which is a good coal storage device in port.

Analysis on Key Technology of Steel Coal Silo

Discharging method of steel coal siloBecause of the poor fluidity of coal, it is very important to choose the discharge method of steel coal silo. For large diameter coal silos (diameter greater than 20 m), we must set up a special discharging device, while most of the small-diameter silos adopt the self-flowing inverted cone outlet. The cone wall angle of the discharge port should be more than 45 °, and the inner wall is pasted with cast stone on the surface to increase the wear resistance and reduce the discharge friction resistance. Generally, one steel coal silo may have single outlet, double outlets, four outlets, nine outlets, or other forms. In order to prevent eccentric discharging and ensure the stress balance of the main silo structure, these outlets are symmetrically arranged and opened. The middle one is commonly the main outlet, which is larger than the others. Therefore, the capacity of the belt conveyor used in the middle should also be greater than belt conveyors on both sides.

The delivery method of coal

Belt conveyor is the most frequently used transporting device in the coal handling system of coal silo. They are installed in different locations to assist in the delivery of coal. In our daily work, the coal will be first transported to the top of the silo by belt conveyor and then fed into the silo by the conveyor mounted on the silo. When the unloading system is opened, the coal will be discharged to the belt conveyor under the silo through a 50° inverted cone bottom and then be shipped away. An electronic belt scale is installed at the head of the conveyor, which can easily carry out coal blending according to the proportion.

Insulation measures of steel coal silo

All of the coal contains a certain amount of moisture. In order to ensure the smooth handling of coal in winter, we need to take some insulation measures. The commonly used method is to cover the coal silo wall with an insulation layer of 80 ~ 100 mm thick. The insulation material best use polyurethane foam or rock wool. If the coal is stored in the silo for a long time, the thickness of the required thermal insulation layer should be calculated according to the temperature difference inside and outside the silo, the storage days, and the thermal conductivity of the insulation layer. It is unsuitable for coal silo to regard heating as the isolation measure because the cost is high. Besides, the temperature stress caused by the alternation of cold and hot will have an adverse effect on the silo structure.

The corrosion of coal on steel coal silo

As we know, coal has strong corrosivity to steel. For solving this problem, we can use special anti-corrosion coating to treat the inner wall of the steel coal silo and then do some regularly inspect and repaint.

Spontaneous combustion of coal in steel silo

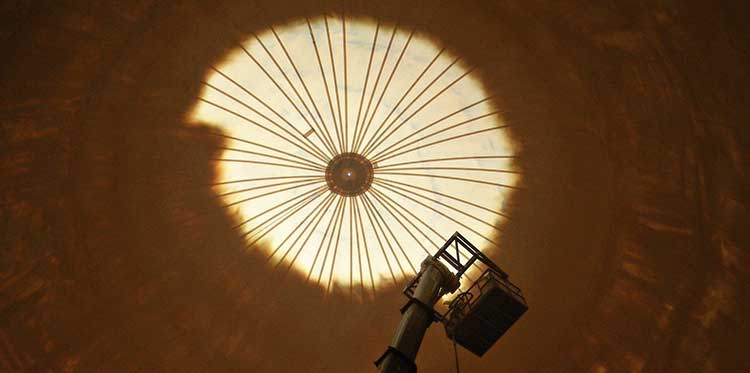

The thermal conductivity of coal is small so the speed of its heat diffusion to the surrounding is very slow. After the coal is stored in the silo for a long time, its temperature will rise. When the temperature and combustible gas concentration in the silo reach a certain value, spontaneous combustion will occur easily. Therefore, we must take effective measures to control the coal temperature inside the silo.

- Adding a thermal insulation layer outside the steel silo wall can not only prevent the coal from freezing in winter but also keep the coal from heating up due to the high temperature outside the silo.

- We can build a ventilation system in the coal silo to exhaust hot air in time to decrease the temperature.

- Adding inert gas into the silo to prevent coal spontaneous combustion or dust explosion.

Get In Touch With

Español

Español