How to Get Rid of the Unloading Difficulty of Large Steel Silo?

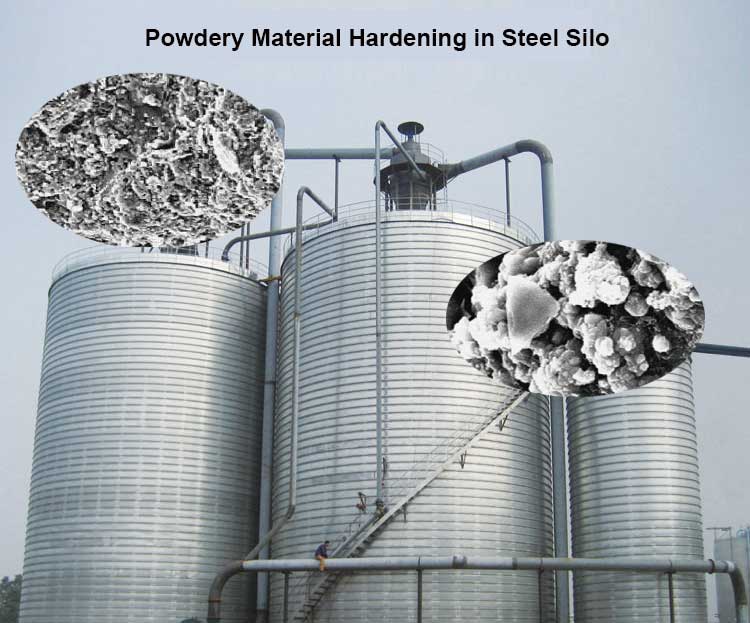

The powdery material stored in a large steel silo is always affected by surface energy in the storage process. The closer the powder is, the greater its adsorption capacity is. The adsorption capacity of the powder in the steel silo is greater functioned by silo wall constraint and the pressure of powder itself. In actual production, due to the effect of moisture content, the powder is inevitable to have the phenomena such as compaction, hardening and stickiness, resulting in substantial waste of resources. Therefore, it is crucial for the material to have a good unloading system of the steel silo.

One of the advantages of the FLYER steel silo is that the unloading system is well designed with high emptying rate. But how can the unloading system of the FLYER steel silo be designed to achieve such a high aim?

The emptying rate of steel silo refers to the percentage of the unloaded material from the silo and the total material. The emptying rate directly reflects the practical quality and performance of the steel silo. It is the main performance index of the steel silo. When the unloading situation of steel silo goes deteriorated, the deposit of the stored material in the silo increases reversely. The material deposit and slow speed of the unloading can make effective volume reduction and cause low emptying rate. The emptying rate is low to not only make the steel silo play no good unloading effect, but also result in reducing the economic benefit.

How to get rid of the unloading difficulty of large steel silo? The FLYER adopts the measures as follows:

-

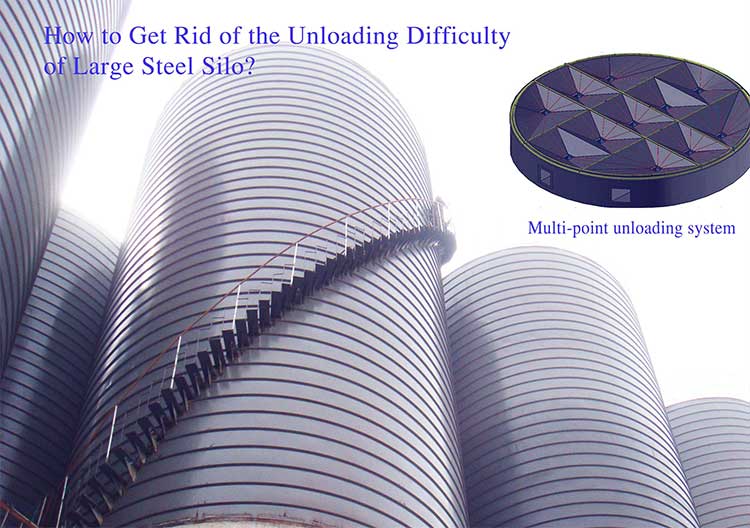

Multi-point Unloading

Steel silo, especially large steel silo, is directly unloaded of the material from its middle part of the inverted cone bottom, so the material at edge of the silo is always left there and form the so called dead zone. This is the reason that the emptying rate of the silo is greatly reduced. At present, the conventional technology of construction of steel silo popularly cannot be used to solve the serious problem of unloading. At the period of after-completion of the silo, it is okay. But with the extension of time the unloading, the problem is getting worse and worse. For example, a company’s fly ash silo (30 thousand tons and 31m Dia.) has to be unloaded from only 4m Dia. of unloading space when the problem is serious. The rest parts are deposited as dead material and material dead zone in the silo. Afterwards, the silo is utterly blocked and cannot play the unloading work. When clearance, we have found out that its repose angle has up to 70°to 90°, the unloading system has completely lost performance.

We are sure to say that the bigger the storage tonnage of powder material, the lower the emptying rate is. This is decided by the bottom area and storage pressure of the silo. The unloading technology of existing large steel silo is mostly gas transmission, tube homogenization. But the above technology is only suitable for medium powder steel silo and cannot be as the leading unloading equipment of large steel silo. Due to the large steel silo is huge in storage, so the material at the bottom of the powder silo bears under enormous pressure from the upper part of powder material, its density increases relatively. Reaching its certain limit, the powder will agglomerate, which leads to all out the unloading difficulty.

To solve this problem, our FLYER Company has designed out a more environmentally and friendly multi-point unloading technology. The steel silo material in the silo applies multi-point method, which have obvious advantages. First of all, the method has big unloading angle, whose strength combines with gravity. So the unloading process is smooth, its emptying rate is high. Even if long-term storage, it can still ensure the material to be unloaded normally. Secondly, through the supplying of Roots blower, the fluidization rods convey air outwards continuously, the material is always in fluidized state to prevent stickiness and hardening phenomenon. Finally, because of the multi-point unloading, so when some part fails, the material can be temporarily unloaded from the other areas without affecting the normal work. At the same time, the unloading points are arranged reasonably, which provides convenient maintenance for the future.

In the powdery storage industry, with the application and development of science and technology, the method is the ultimate solution to the unloading difficulty of large steel silo. The development of any technology needs time to verify itself. With the help of it, the best emptying rate has reached 98%, which creates great economic benefits to the enterprises.

-

Moisture Proof Measures

The high moisture content of powder material itself is prone to result in the degradation or failure of the fluidization performance of the material. In this regard, the users should strictly control the moisture content of material before lowering the moisture rate of the material to the minimum. The drier the material is, the better fluidization is. If the cement foundation at the bottom of the silo layer is not completely dry without taking effective measures, the material at the bottom of the silo will become damp and its humidity will also increase, which will cause the material to get into blocks. The situation is going to cause the unloading difficulty. In addition, some users start to use the silo before its cone is dry, so the implementation of moisture proof measures of the bottom of the silo is particularly critical. Our company has decided to paint surface coating to as necessary waterproof material to improve the bottom dryness. The surface of moisture proof layer is smooth and clean to help convey material circulation.

As s new generation of large steel silo, combined with international advanced technology it is a combination of fail and success of all series of steel silos, which completely solve the unloading difficulty of powdery material in a large storage silo. Single silo can store 10,000-100,000 tons of various powder and granular materials, whose emptying rate can reach 95%-98%. It is the ideal storage equipment of powdery material for manufacture enterprises.

Previous:How to Ensure Safety of Steel Silo?

Get In Touch With

Español

Español