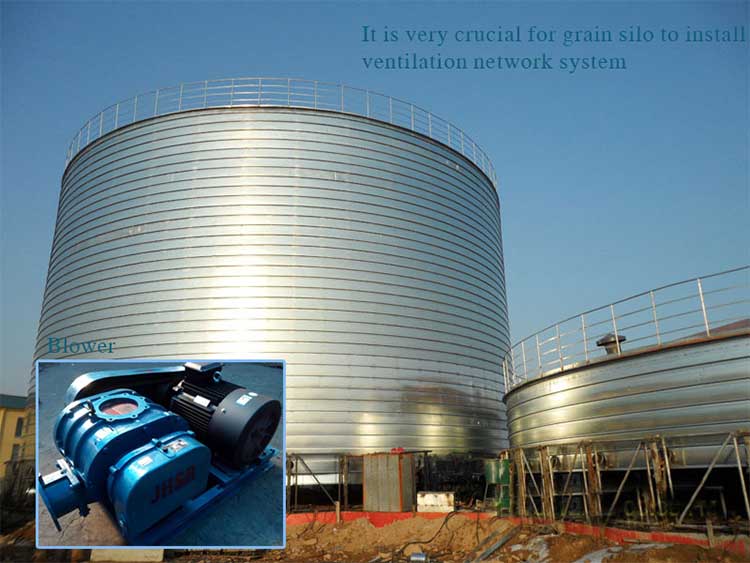

It Is Very Crucial for Grain Silo to Install Ventilation Network System

Ventilation System of Grain Silo

Ventilation is the first security barrier in the grain storage silo. If no ventilation system of grain storage silo, the silo will not store grain. This shows the importance of ventilation. Good grain steel silo must be equipped with reasonable attached machine, or it is incomplete to safely store grain. Today we talk about understanding of the importance of ventilation structure of steel silo and the important machine—blower.

The design of ventilation network system of steel silo adopts a plurality of specific pipeline connecting with the blower, which can make the grain silo body rapidly get cooling and dehumidification without dust, and can ensure the quality of the grain silo body and increase the added value of products. At the same time at the bottom of steel silo body conical hopper design and conveyor installation are adopted to ensure all the grain to fall to the bottom, which is conducive to unload it fully and fast by the conveyor and greatly improve the unloading and transportation efficiency. The design is to not only save time and labor, but also add ingenious idea of artificial ventilation network system of steel silo, which is very suitable for popular application in a large area. The ventilation network system of steel silo overcomes the defects of the existing technology successfully and provides a highly efficient system.

The ventilation network system of steel silo includes concrete base, silo body, silo cover, insertion ventilation pipes, inner ventilation pipes, outer ventilation pipes, the blower and the conveyor. It has the advantageous characteristic as follows: the body of steel silo is placed on the concrete base, and the insertion ventilation pipes are inserted between the silo body and the silo cover. The inner ventilation pipes are located in the silo body. The blower is connected at the bottoms of the inner ventilation pipes and the outer ventilation pipes. The conveyor is arranged on the bottom of the silo.

At the bottom of the steel silo is provided with a conical hopper outlet that here is installed with an unloading solenoid control valve. The valve is paralleled with the conveyor. The two pieces of insertion ventilation pipes are respectively the left insertion ventilation pipe and the right insertion ventilation pipe. The inner ventilation pipes are connected with the silo cover connected and fixed on the center position of the silo cover. Inside the silo body, the inner ventilation pipe and the insertion ventilation pipe connected at the bottom and is also done with the blower and the outer ventilation pipe. The number of steel silo body is four.

The Structure Characteristics of Roots Blower

- The intake and exhaust of the blower adopt the design of spiral shape, which makes the processes of intake and exhaust work as the orders according to the direction of spiral lines to avoid the fluctuation noise and vibration when the blower starts to exhaust air. The blower uses impedance composite muffler to reduce noise.

- The adiabatic and volumetric efficiency are high, and therefore it is energy saving. The rotor of the blower adopts the advanced composite curve, so the meshing is more reasonable and then the volume efficiency is increased.

- The performance is stable. The key parts of the rotor, shell, wallboard, shaft, etc., all adopt the advanced numerical control processing equipment. The impeller does not need to study and can completely interchangeable as the assembly.

- The vibration is small. Although the rotor has been precisely machined and become a state of balance, the high-precision dynamic balancing equipment is still used to balance. So the blower is always running with no vibration.

- The use of high-precision and high-hardness of the synchronous gear is not only to extend the life of the blower, but also to effectively reduce the noise.

- The blower adopts the bearings imported from Japan or Germany and the rubber belt imported from South Korea or Taiwan, so the quality is more reliable.

- The released air is clean without any oil and dust. The sealing structure of the blower is reasonable, so the oil cannot enter the enclosure shell and the air is clean.

Anyang Flyer Steel Silo Co., Ltd. can accomplish complete projects of spiral steel silos for grain with the advanced ventilation network system and the blower and help our client to provide excellent service. If the client wants to understand or acquire relevant information and documents on ventilation and blower of grain steel silo, please feel free to contact with us. We here hope to receive your message because we know good communication with you is must-be way to start opening the door of success and cooperation

Get In Touch With

Español

Español