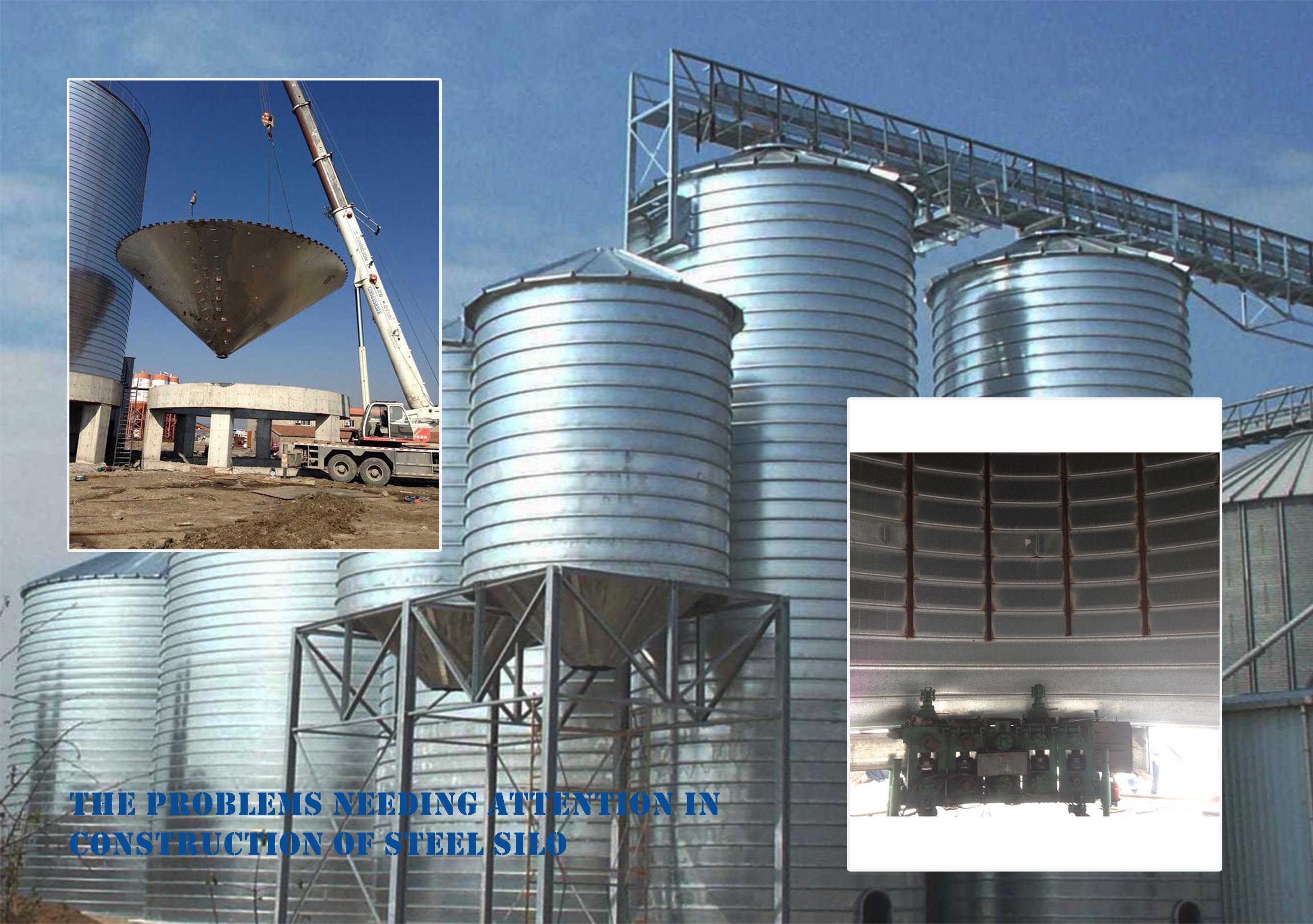

problems in construction of steel silos

As a type of mature storage, steel silos have become very popular in the world after a development of more than 30 years. It has now been widely used in each link of the storage and transportation, and has already become the symbol of industry modernization in bulk storage. This was originated from its superiorities:

First, excellent applicability

Steel silos have realized the mechanization and automation in the storage industry, and have performed so well in many aspects, including loading and unloading, monitoring and processing, ventilation, temperature measurement, etc.

Second, economic price

Among all the storage forms, steel silos’ construction cost is the lowest. Not only the silo parts but also their foundations can be made with relatively low cost. All their construction costs are just equal to 1/2 those of a reinforced concrete silo. Compared with the brick storage warehouse, it can save 20% investment. And with the steel price decreasing, the construction cost may grow even lower.

Third, superior construction

Constructing steel silos can be very efficient. The advantages in silo construction include simple foundation, short construction period and weather immunity.

Since we have learned these superior features of steel silos, now we should pay some attention to the construction problems:

1. Material selection. In China, we usually choose common types of steels, Q235 steel is the most popular one. We can easily get it from many steel& iron companies in a economic price. If the thickness of the silo wall exceeded the calculated production capacity of the equipment, we could use low alloy steel to replace Q235 steel. Generally the walls of steel silos should be galvanized to meet the corrosion protection requirement. Therefore, the galvanized layer is a very important index for steel silo construction, which would directly affect the service life of the steel silo. The standards we use in China are consistent with the international standards, 400g/m2 is the thickness of the galvanized layer of our products.

2. Spiral steel silos and assembly steel silos. The thin-walled types of steel silos are the most popular in types in the world now, they include spiral steel silos and assembly steel silos, and these two are different in certain characteristics due to their different structures.

A. Spiral steel silos

A spiral steel silo is made by continuous undercutting of hot dip galvanized steel coils and has uniform color. Its high air tightness allows it to store water, oil and other liquid materials. Because of its smooth inner wall, the requirement for thickness is greater than the assembly steel silo’s.

B. Assembly steel silos

The characteristics of assembly steel silos:

a. In the aspect of material selection, we can use the hot galvanized coil or plate as well as the electrical-galvanized plate, which we can get in a more convenient way.

b. All the parts of the silo are replaceable standard components. When some of them were damaged or rusted, we can simply replace them and prolong theirs service lives.

c. The silos can be transported to another place easily, which makes them especially suitable for rental sites of the users.

d. Using the outer column forms of steel silos is good to the food stored in the flow.

e. Their air tightness is not that high, but we can use the silicone sealant to reach the tightness requirements.

f. These silos can help develop double insulation structure, and this will not largely increase the costs.

3. The foundation forms of the steel silos. The foundation forms include the flat bottom type and the conical bottom type:

The flat bottom type is suitable for great diameter silos that equipped with cleaning machines or are manual cleanable. They can be constructed in easier way and have lower prices.

Considering the convenience of the gravity unloading, the conical bottom type steel silos have become another popular type. The conical bottom types can be divided into full-steel conical type, semi-steel conical type and cement conical type. Judged from their practicability, we can say that these three types do not have much difference. But there is the backfill method which requires to backfill out a conical bucket. Although this method can reduce the construction difficulty, it will waste steel silo materials, lower the storage capacity and increase the civil engineering workload.

Therefore, to choose a construction project for steel silos, we must consider the above aspects to ensure the performance and the profits be maximum and the investment be worth while.

FLYER Company has a rich experience in the design and construction of modern large spiral steel silos. We can solve complex design problems you may meet effectively. If you have any problems or requirements, please feel free to contact us. We will provide you any information you need. Expect to build a long lasting partnership with you!

Get In Touch With

Español

Español