The Imporatance of Steel Silo Maintenance

The Importance of Maintenance

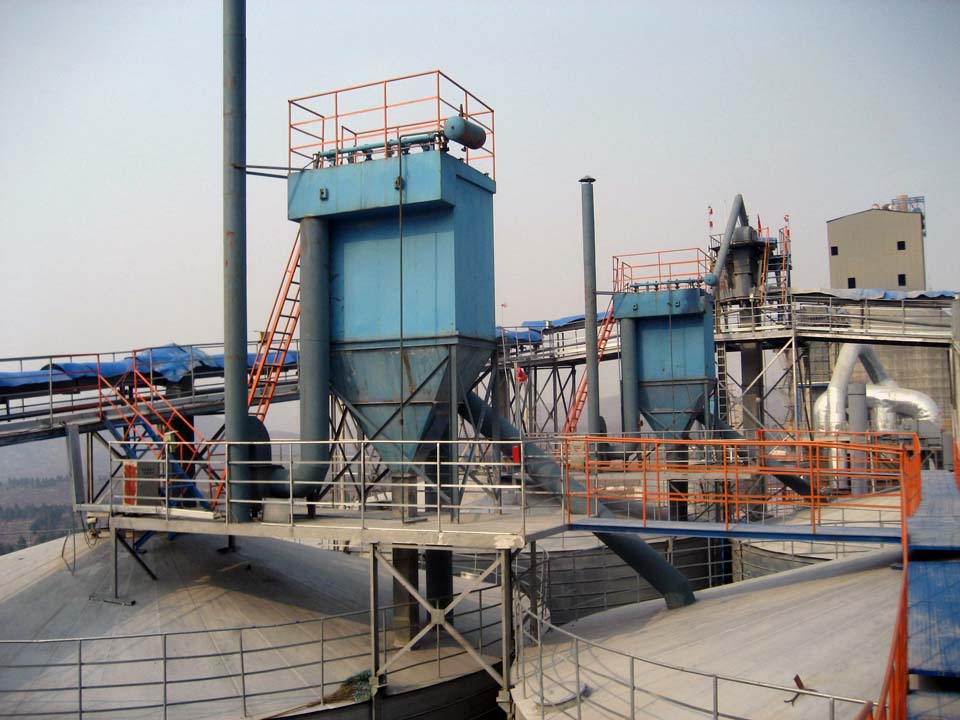

Nowadays, steel silos are adopted in many fields of industry and agriculture because of its wide applicability. They can be used as cement silos, grain silos, fly ash silos, etc.Good maintenance and regular repair for storage silos can not only ensure their long-term and safe use, reduce their maintenance rate, but also extend their service life.

Inappropriate operation and poor weather conditions can lead to damage and corrosion of the storage silos. Without regular maintenance, the storage silos will not be able to function well, and even will collapse under some occasions.

Therefore, routinely inspection and maintenance is a very important job for storage silo users, and a job must be done well.

How to Maintain Steel Silos

I. Daily Inspection

a. Air-tightness inspection. Leaking accident is frequently seen on storage silos, especially on the connection parts. So air-tightness inspection is necessary in daily use.

b. The level gauge must be ensured that it is in normal use. Do not over load material.

c. The vent hole of the top of the storage silo and the plug of the axial fan should be checked in daily use.

d. Any modification to the silo body is strictly prohibited.

e. To prevent the cracking of the bin, the galvanized and spray paint should be treated in time when corrosion occurs.

f. Keep distance from the storage silo in thunderstorm days. To avoid lightning strike and the loss of personnel and property.

g. Frequently check the wall deformation of the storage silo and the bolt connection of the stiffened wall panel. If the bolt is found to fall off, it should be fixed immediately.

h. Regularly check the door frame of the storage silo and the adjacent side board, to see if there are any signs of deformation and cracking, and take the maintenance measures according to the actual situation of the storage silo.

i. Often check the joint parts of the cone, the welding place, the surface of the cone and so on. If there are abnormal conditions such as welding deformation and weld seam cracking, the feeding should be stopped, to prevent further damages.

II. Regular Maintenance

a. The maintenance for the silo top platform should be performed regularly to prevent rain leakage and steel rust. Check the top weld of the whole welded crest on a regular basis, and determine the necessary anticorrosion treatment according to the inspection. The inspection of the corrosion and leakage of the surface of the process holes (including ventilation holes, Manholes, thermometer holes and seat, etc.) is carried out regularly.

b. The maintenance of the process holes in the steel silo during the use of the steel silo is very important. Check the situation of the corrosion proof requires regular technological holes inspection of steel silos. This is to avoid improper maintenance impact on the service life of steel silos. (Note: the process holes include a manhole, a ventilation hole, a seat, a temperature measuring hole and so on. The user must not miss it when it is overhauled. )

c. In the user's use and maintenance of steel silos, we need to pay attention to regular repair and maintenance of silos, and do well in details.

1). Each time the steel silo is emptied, it is necessary to inspect the silo body of the steel silo. One aspect is to see if there is a cracking around the silo door of the silo. Another aspect is to look at the silo seal of the silo. In addition to the integrity, the user also needs to check and strengthen the connection between the rib and the wall.

2) When the user fills or empties the steel silo, it is necessary to check whether the silo wall is deformed. In particular, it is necessary to carefully observe the sensitive parts such as the profile legs of the steel silo, and record and archive the inspection results. Therefore, the wall of the steel silo is subjected to anti-corrosion treatment according to the results of each inspection.

d. Users of the steel silo need to check the installation bolts of the vertical ladder each year to prevent loosening. During the inspection, it is necessary to check whether the materials used are damaged, and take repair measures according to the inspection conditions.

e. Before the onset of the rainy season each year, users should carefully check the corrosion of the steel silo. Attention should be paid to the rainproof inspection of the joint with the steel silo, and the rainwater should be prevented from entering the steel silo from this point, resulting in deterioration of the material in the steel silo.

Español

Español